Notizie sul cambio MT-75 adotato sul Ford Transit ed altri veicoli Ford a trazione posteriore

versioni cambio MT75 a confronto

trasmissione MT75 "W8" rapporti distanziati: 4,17; 2,24; 1,47; 1,00; 0,82; R 3,76

trasmissione MT75 "C8" rapporti ravvicinati: 3,89; 2,08; 1,34; 1,00; 0,82; R 3,51;

trasmissione MT75 "E8" rapporti ravvicinati: 3,61....(il resto identico a "C8")

Tipo "G": 4,06; 2,16; 1,38 (overdrive 1,07); 1,00 (overdrive 0,78 ); R 4,29

Tipo "N" (fino al 1988): 3,90; 2,87; 1,38; 1,00; 0,81; R 3,66

come si legge lo "sticker" di identificazione del Ford Transit

trasmissione FT150/190 mkV (1994-2000)

trasmissione 137cv mkVI (2000-2006)

The gearbox casing is all aluminium and due to the integral bellhousing, swapping gearboxes between different models with different engines can be a very complex and involved job best left to the professionals. Certainly not a 30 minute, quick 'in and out' job. Even the 2.0 pinto and the 2.0 Cosworth (essentially the same block) have different bellhousing patterns. Often, getting a gearbox to bolt up and work may require several donor gearboxes to be dismantled for parts. Most swaps can be done, but as parts are getting more rare and expensive, 'patience' might also be on your shopping list.

The MT75 gearbox was fitted to several cars and vans:

| Engine | 1st | 2nd | 3rd | 4th | 5th | Rev |

|---|---|---|---|---|---|---|

| 2.0 litre DOHC 8v | 3.89 | 2.08 | 1.34 | 1.0 | 0.82 | 3.51 |

| 2.0 litre DOHC 16v | 3.61 | 2.08 | 1.44 | 1.0 | 0.83 | 3.26 |

|

2.3 litre DOHC 16v May '97 |

3.61 | 2.08 | 1.44 | 1.0 | 0.83 | 3.26 |

|

2.3 Litre DOHC 16 May '98 |

3.61 | 2.08 | 1.36 | 1.0 | 0.76 | 3.26 |

| 2.5 TCi Diesel | 3.61 | 2.08 | 1.36 | 1.0 | 0.76 | 3.26 |

There are several bellhousings, input shaft lengths, gear lever

positions, flywheel are different etc.

The Ford Sierra 2.0 DOHC bolt pattern is shown in the drawing below.

It is very similar to the 2.0 Cosworth MT75 but has less bolts

and the starter motor is in a different position.

As you can see there are a number of bellhousings:

Although the top bolt pattern is similar to the 2litre Cosworth

Bellhousing the bottom bolt pattern is different.

![]() Download

the 2.0 DOHC MT75 Gearbox bolt pattern and dimensions

Download

the 2.0 DOHC MT75 Gearbox bolt pattern and dimensions

The Transit LT350 2.4 diesel Gearbox is available with 3 and 4

bolt propshaft flanges.

![]() Download

the LDV Single Rail Gearbox Service Manual here

Download

the LDV Single Rail Gearbox Service Manual here

I'm not sure what this one is but it is an MT75.

From the Bellhousing it looks like a V6 and from the gear level

position it looks like a Transit. The cluch lever sugests it is Left

hand drive.

I know they produced a couple V6 ambulances, so maybe it's something

similar?

Then there is also the:

There are also different length main shafts, different clutch and flywheels etc.

The gearbox housing is made of aluminium and consists of two

halves

The usual gear extension does not apply to this transmission. This had a weight saving of approximately 7.0 kg and reduced the entire length.

The transmission was improved by the following measures:

Gear ratios were tuned to provide good performance and economy. By changing from 4th to 5th engine speed can reduce engine speed by 1000rpm. When this gearbox came out 4 speed was norm, 5 gears reduce engine emissions, noise and wear.

All of these help to optimise the ride quality and driving comfort.

|

Ford MT 75

5-speed manual transmission |

Previous

5-speed manual transmission (Type 9)

|

|

|

Maximum Torque

|

300 Nm - 221 ft/lbs

|

220 Nm -162 ft/lbs

|

|

Weight

|

35,0 kg

|

42,0 kg

|

| Transmission length |

638 mm

|

772 mm

|

| Gear wheels (all) | Needle bearing | no needle bearings |

| Gears | 2-piece welded | one-piece |

| Reverse gear | synchronized | not synchronized |

| Clutch and gearbox |

Two-piece die-cast aluminum Gear extension is not necessary. |

Three-piece cast iron. Gearbox extension of die-cast aluminum |

| Oil Capacity | 1.2 Liter | 1.9 Liter |

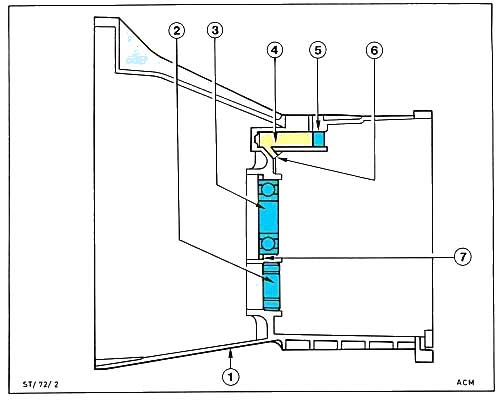

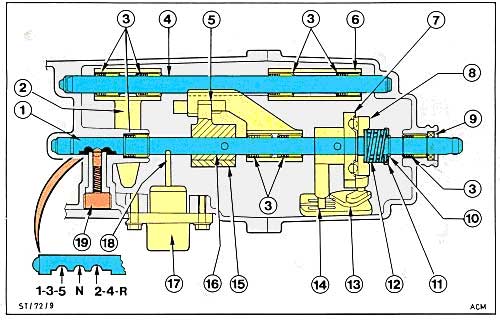

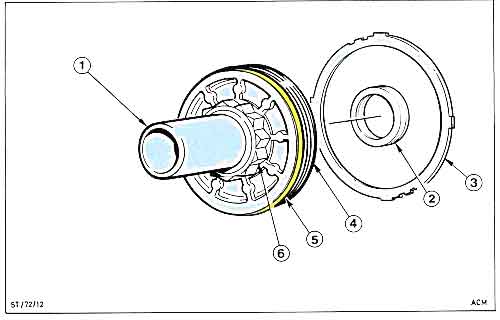

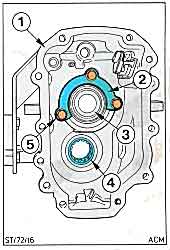

The front gear box features three bearings

The drive shaft ball bearings are sealed with an oil seal in the

guide sleeve. The thread of the guide sleeve within gear housing is

sealed with an O-ring seal.

The roller bearing and the bearing bracket from the transmission are

also sealed with an O-ring seal. The selector shaft has a ball

sleeve bearing in the front gearbox.

The bore-selector shaft has a ventilation hole for the shift shaft.

All bearings in the front housing are replaceable.

To adapt to the different engine options and for left-and right-hand

drive vehicles, different front gear housings are available.

Note:

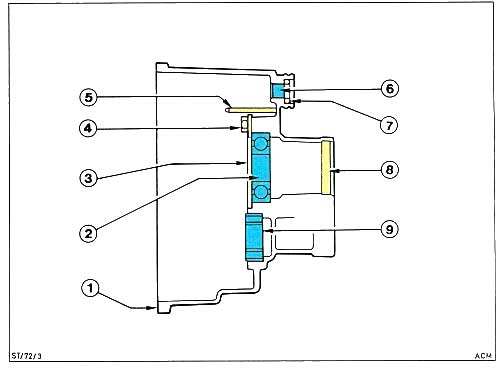

There are three bearings in the rear housing:

The countershaft ball bearings are pressed into the rear gearbox.

The ball sleeve bearing and the selector shaft is sealed by a radial

seal at the rear gearbox.

The main shaft is sealed with a radial sealing ring.

The locking pin in the rear transmission housing is used to prevent

rotation of the selector mechanism.

All bearings and radial seals are replaceable.

Note:

The main shaft ball bearing must point to the inside cover of the

transmission housing.

The roller bearings (inner and outer bearing) for the reduction

gearing must be from one manufacturer.

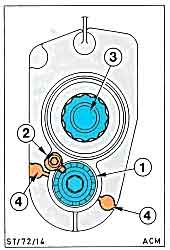

The two halves of the transmission casing are held together by 10 bolts. Two guide pins center the two gearbox halves. The switch for the reversing lights is attached to the front gearbox housing. The switch is actuated by a selector shaft pin.

The figure shows important attachments and fixtures

There is a ventilation air hole in the locking screw for the

locking plate.

When repairing, ensure that the vent is free of dirt and debris. A

clogged transmission vent can create unwanted pressure. A blocked

vent will result in Oil leaks, spills and lack lubricant.

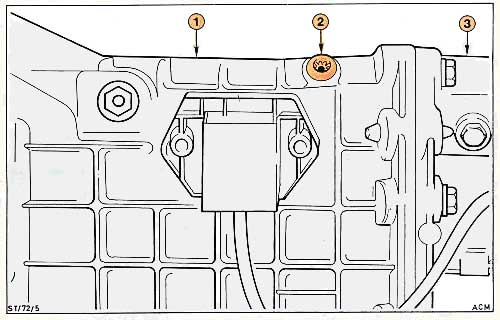

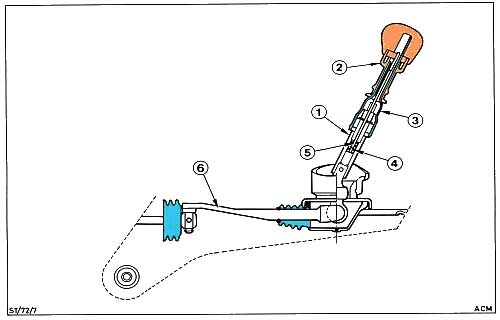

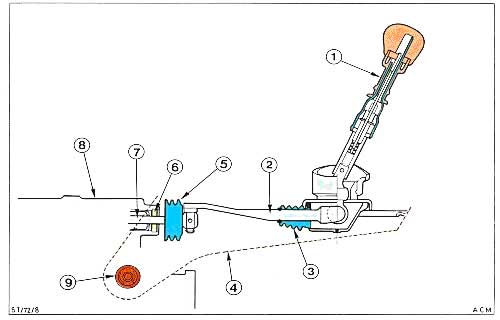

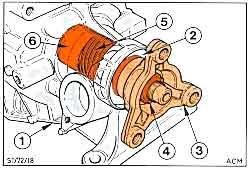

The shifter is a complete unit and in the case of failure must be

completely replaced.

The shifter is not the usually fixed to the gear extension, but onto

the control beam, which is attached to the gear housing.

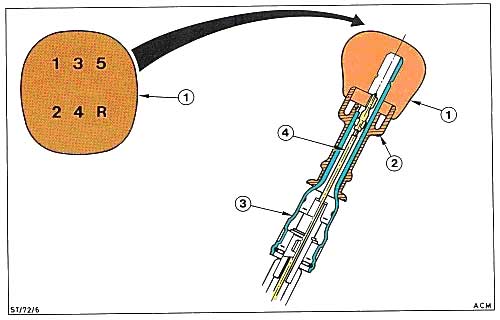

Gears are selected using the shift lever, the outer plate and inner shift shaft. The reverse gear is synchronized. The reverse gear can be selected only in the neutral position and by pulling up the reverse lock on the gear lever. The forward gears are seected in the usual manner.

The outer transmission circuit consists essentially of the gear lever, the arm and the switching beam. A setting of the shift rod is not provided. The switching beam is fixed at four points on the rear gear housing. To remove the transmission, the gear shift lever is removed.

The internal selection assembly consists essentially of the shift

shaft, the shift forks, shift interlock and the shift gate. The main

selector shaft is mounted within a ball bearing sleeve. The main

selector shaft is moved from the outer plate axially and radially.

The main selector shaft contains the following components:

On the side selector shaft is:

A light press fit helps guide the secondary selector shaft in the

front and rear gear case.

The shift forks are mounted on the shifting shafts with radial ball

bearings.

Note:

The ball sleeve bearings of the main and secondary shafts and the

shaft of the shift forks (total 8 pieces) are identical.

Before installation, the ball sleeve bearings are wetted with

specified gear oil.

The shift gate is secured with two fitting bolts on the rear

gearbox.

The reverse lock is attached the shift gate and secured with a clip

.

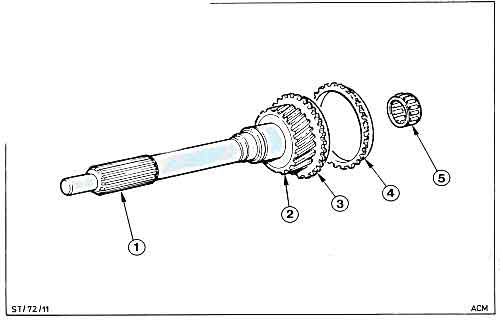

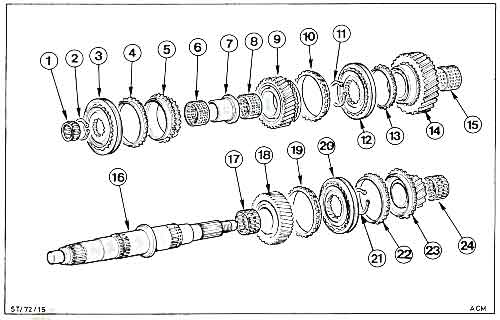

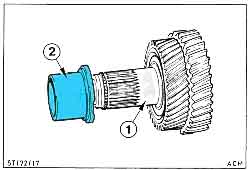

On the drive shaft is the drive wheel of the layshaft and the

synchronizer for the 4th Gear. The drive shaft is mounted in the

front gear case in a ball bearing. The ball bearing is held axially

by a retaining ring in the transmission housing.

Note:

There are different drive shafts for the different gear ratios and

engine versions. The drive shafts therefore differ not only by the

number of teeth, but also in length. Therefore, it is important that

the part number, engine and vehicle model information is used to

obtain a replacement.

The guide sleeve is made of aluminum and is screwed into the front gearbox. There is a thrust washer in the guide sleeve, for the front bearings of the main shaft. The guide sleeve has a radial seal and an O-ring, they can be replaced in service. Before fitting, clean the threads of the guide sleeve and the threads of the front transmission case. Prior to driving, the radial seal and the O-ring replaced and are wetted with specified gear oil. The guide sleeve is screwed in with a special tool 16-040 in the front gear housing and tightened to 150 - 170Nm.

The bearing for the countershaft is held in position by the bearing housing and sealed with an O-ring seal. The O-ring seal can be replaced in service. The housing is made of aluminum and is screwed into the front gear case and secured with a locking plate. The housing can be installed with a commercially available internal hex wrench (17.0 mm).

Before installation, clean the thread of stockholders and the thread in front gearbox housing. Then wet the O-ring seal to be replaced with specified gear oil.

After installation, the bearing holder is tightened to 20 ± 5 Nm and then rotated by 60°. Then with two blows of a brass spike and hammer hit the slugs, so that there is bearing clearance. It must be possible to turn the input shaft by hand. This ensures that the bearing is seated. Thereafter, the bearing housing is secured with the locking plate (see workshop manual). 1. Bearing Housing - Allen (17.0 mm) 2. Locking plate (screw with 9.0 to 11.0 Nm) 3. Guide sleeve - drive shaft 4. Slugs

The main shaft is mounted in the rear transmission housing in a ball bearing. The drive shaft in front of the main shaft is guided by roller bearings. The ball bearings are held in place by a retaining plate in the rear gear housing. The mounting plate is secured with 3 screws in the rear gearbox.

All Gear wheels are mounted on needle bearing. Thus the shiftability transmission is significantly improved. The needle bearing of 3. Gear Selection wheel running on an internal bearing race. The inner bearing race and the needle bearing are paired, so must be replaced together.

To renew the Internal bearing race of 3rd Gear wheel is heated

with a heat gun (100 ° C), released with two suitable levers from

it's seat and taken off of the main shaft with a standard 2-arm

puller. The Internal ring must not be overheated when heated.

The gears and synchronizer are held in place by three retaining

rings. The retaining rings are available in different strengths in

order to ensure the required mounting tolerances.

The main shaft is sealed in the rear gear housing with a radial

sealing ring. This seal can be replaced with the transmission

installed.

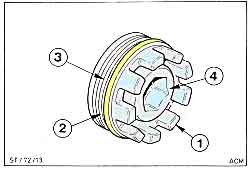

The Gear wheels of the MT 75 transmission are made of two parts:

The more recent Gear wheels were manufactured in one piece. For

technical reasons, therefore had an approximately 4.0 mm wide

machined nut placed between the running and the clutch teeth.

To optimize the smoothness compared to the previous design, the

2-piece gear design made it possible to tune the running gear after

hardening and correct any hardening distortions.

After processing of the gear body and the cone clutch teeth, both

parts are joined together so that as the later weld hardens no

carbon forms.

After the curing process, the cone is separated from the tooth body

to (grind) treat the running gear.

The advantages of this new technology are:

Ford Transit-350-ldv-mt75 (.pdf)

Torna alla pagina precedente GO BACK

il sito www.giordanobenicchi.it NON ha alcun contatto con il produttore dei veicoli ricreazionali/meccaniche, tutte le informazioni pubblicate nelle pagine di questo sito sono frutto di esperienza personale.